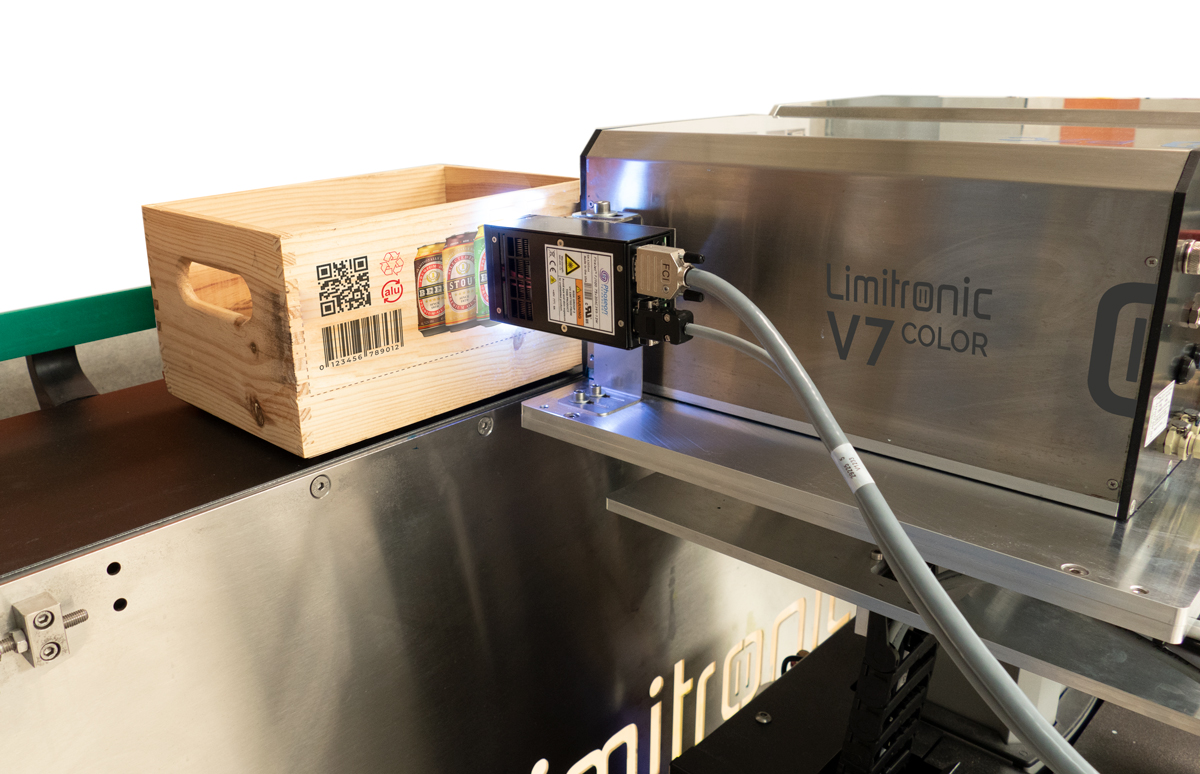

Limitronic inkjet equipment can print any type of data: images, logos, barcodes, QR codes and texts; on any type of substrates: corrugated board, plastic, EPS, electronic devices, promotional products, protecting covers, metallic surfaces, etc. For this reason, the use of this technology is not limited to the packaging but the product itself. In this respect, inkjet printing is a perfect traceability instrument for internal and external processes.

Digital

Only inkjet technology allows printing variable data, which means having different information printed on each product or logistic unit.

Hight resolution

High resolution inkjet printing provides optimal and reliable reading of codes for automated systems (barcode and QR readers).

Superior technology

Limitronic inkjet printing systems mean a qualitative technologic leap with respect to hot melt printing or labelling.

Inkjet is a clean printing process. It is cost-competitive, it does not require maintenance and it has a very low power consumption compared with hot melt inks. On the other hand, inkjet technology does not require stops in the line for consumable replacement, as the traditional labelling processes do.

Efficiency

Digital inkjet printing is an efficient technology that does not interfere in the manufacturing processes. Limitronic printing equipment are reliable and autonomous and do not slow down production rates. They are also a helpful tool to implement Industry 4.0 practices

Flexibility

Any information to be printed onto the product or packaging may be a dynamic file that is quickly updated by the printing system. Furthermore, inkjet is a non-contact technology, able to print on complex surfaces. As a result, inkjet printing is a versatile solution in manufacturing and packaging lines.