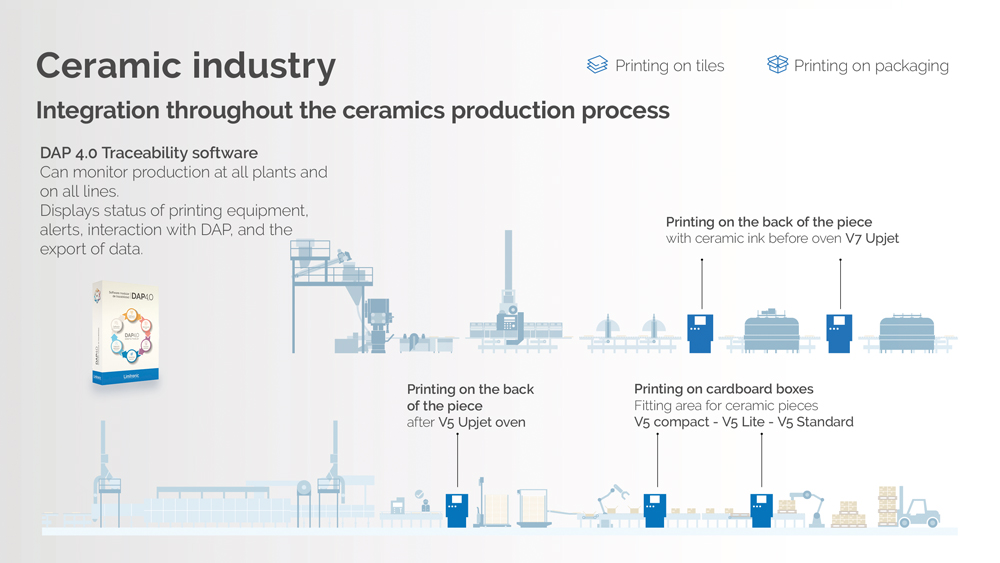

The Spanish ceramic sector, one of the most powerful in the world, is constantly evolving and expanding, and requires new technologies to optimize its productivity. Limitronic's experience and specialisation in this sector has facilitated the development of new engineering and printing stations that allow the co-communication between printers in an intelligent way, automating the process and making it more efficient.

We have a long experience, as we were born, grew up and learned together. We were pioneers in proposing a barcode system, to have a traceability of the products at the time of packing. Limitronic was the first company to address this need in a truly technological way, with breakthroughs such as

- The implementation of the EAN code in this industry.

- Coding for standardised tone and caliber.

- Colour and high resolution printing.

- Vertical UpJet printing.

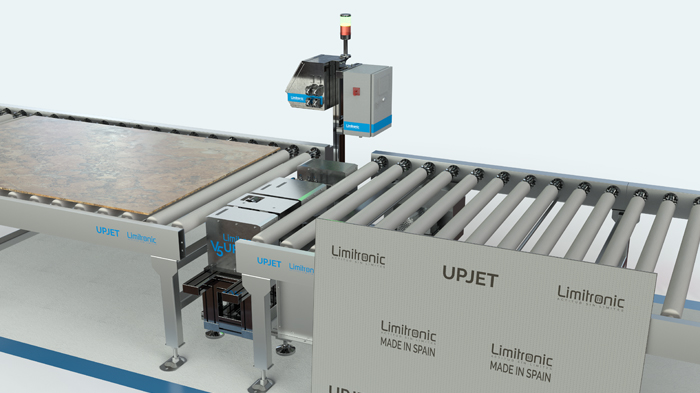

The latter is a major development. In 2016, we introduced the first UPJET printer, which allows printing upwards on the production line and in high resolution. It can print all kinds of information such as collection, thickness, manufacturer's brand, add logos and variable data such as Qr codes and barcodes on the back of the part. Prints are sharp and durable.

The UPJET printer models (V5 and V7) print directly on the back of the ceramic tile.

These printers are especially suitable for printing large format pieces. A solution for this product that is undoubtedly an innovation in the ceramic industry. Its "single-pass" technology is integrated into production lines without the need to stop production in order to carry out all types of printing such as logos, QR codes, barcodes or references.

It allows brand personalisation and brand protection directly from manufacturing. It is optimised for remote assistance and its high performance guarantees its operation with almost no maintenance.

It prints on all types of ceramic and porcelain tiles and is suitable for all market formats such as countertops, floor tiles of multiple dimensions such as 60 x 120 cm or 120 x 260 cm, coverings and decorations.

UPJET printing is a powerful tool in communication and logistics.

We integrate UPJET printing equipment before or after the oven process, depending on the needs of your production lines. We use recyclable inks that promote circular economy and sustainability.

Benefits of direct digital tile printing

In many cases it is necessary to print information to each piece such as serialisation, batch number, shade or thickness. Also the manufacturer's logo and information to protect the brand and advertise it, in this way the final product also plays the role of an advertising and communicative element.

Protection against imitations

The direct printing on each piece guarantees its authenticity and protects the products from imitations.

Production tracking

Limitronic's digital system allows unique codes to be applied to each product, such as QR codes or barcodes, for easy tracking. In addition, the printers communicate with computers and applications and it is possible to control production remotely, regardless of geolocation.

Definitive printing. Ceramic and MOF (mineral oil free) inks

Unlike adhesive labels that peel off, deteriorate and sometimes produce errors in their application, with digital printing, the marks are definitive, and resistant to humidity, temperature, or rubbing against other surfaces.

Advantages of the personalisation of the boxing phase with our digital inkjet system

Our stations print on all types of packaging and adapt to the production line of the company, to work without pauses and optimize time and performance.

They can print on all 4 sides of the box simultaneously, even before folding. Clear, full-colour prints that are resistant to moisture and transport.

Clearly print variable information such as your corporate image, barcodes, QR codes and single-pass text.

Guaranteed and reliable operation

Limitronic equipment can print in dusty environments and variable temperatures. Thanks to its self-cleaning printhead system, the durability of the printheads is guaranteed.

The printers require almost no maintenance, and their customised installation optimises their operation.

Maximum flexibility and productivity

The stations can print in different areas, such as on the top, bottom or any side. They can print in full colour, at any size or inclination. They can make several marks simultaneously and adapt to the specific requirements of each factory, to minimise execution time. They adapt to a variety of box formats without stopping the lines and with high performance.

High speed quality printing

High resolution photorealistic, full-colour printing. No stops on the packaging line for ink or message changes and using single-pass technology.

Work with a maximum line speed of up to 60 m per minute with the V6 printer.

More energy saving and sustainability

From Limitronic we are committed to sustainability and we direct our studies and actions towards more respectful solutions with our planet.

Energy efficiency is one of the objectives set by the EU for industries and companies. Limitronic printers consume less electrical and gaseous resources, as they only use the energy that is strictly necessary, and their configuration optimises the saving of resources.

Compared to on-part or on-box labelling systems, it is much more sustainable, as it dispenses with plastic, paper and adhesive glue and consumes less electricity. Recyclable inks are used, and there is no need to peel off the labels before recycling the packaging.

Unlike the pre-printed box system, with our technology no packaging is wasted due to regulatory or design changes, as each print is run on-demand. Transport consumption is reduced, electricity consumption is reduced, and our inks are more sustainable.